Iso Newspaper 26v4.icc

Net demand trend. System demand minus wind and solar, in 5-minute increments, compared to total system and forecasted demand. Today’s Outlook charts are designed to summarize forecasts and actual loads. The demand and net demand trend data do not include dispatchable pump loads or battery storage that is charging on the system. Das ICC-Profil „ISOnewspaperv426bas.ICC“ basiert auf den Charakterisierungsdaten „IFRA26.txt“. Dieses ICC-Profil wurde mit basICColor CMYKick v1.2 erstellt. Folgende Parameter wurden bei der. Jan 09, 2019 Iso Newspaper 26v4.icc. Language: English 5. Color Quality and INCQC Tutorial, 29-30 July, Kuala Lumpur, Malaysia. An easy-navigation control panel is located away from the production area offering a clear view of the engraving table. Rotary offset newspaper printing according to ISO standard 12647-3 Colour sequence: K-C-M-Y. ISOnewspaper 26v4.icc and WAN-IFRAnewspaper26v5.icc.

Why do I need to calibrate my screen?

Iso Newspaper 26v4.icc India

Display and monitor types are different, resulting in different outputs, even monitors from the same brand and batch will display the same image slightly differently when compared to one another. Typical screen types are (normal gamut, wide gamut, CCFL, LED, White LED, RGB LED and OLED.

Colour correcting an image on a non calibrated display

You really are up against it when trying to colour correct an image on a non calibrated display, as you’re not seeing the real image located on your hard drive. What you are viewing is your monitors uncalibrated interpretation of the image. Basically put, you’re looking through a window to the image on your hard drive, but the window isn’t showing you the true picture as the colour, brightness or contrast hasn’t been calibrated. What’s going to be printed is anyone’s guess on an uncalibrated system.

Example If you see a green cast on the image, you will add some magenta to get the image to somewhere nearer to what the image should look like. The only problem is that on a correctly calibrated screen there was no green cast and all you’ve done now is add a magenta cast to neutralise the image. The only time you will notice the magenta colour cast, is when you see the printed result. The same can be said for correcting colour, brightness and contrast.

- Image taken on camera and displayed on the back. The back of the camera is not calibrated so is only a general guide.

- Image saved to computer hard drive and is an exact match of what the sensor in the camera captured and the camera settings applied if not shooting in RAW.

- In this example the screen is uncalibrated and the colours are off when viewing the image from the hard drive.

- Magenta level / curve adjustments are added in Photoshop to neutralise the green colour cast which was visible earlier.

- Image looks good on screen and appears to be nearer to what was viewed on the back of the camera.

- Image saved back to the hard drive with colour corrections, but now has a magenta colour cast which was used to neutralise the green colour cast which didn’t exist and cannot be seen on the uncalibrated screen.

- Image printed will also show the magenta colour cast as you’ve tried to colour correct something that you couldn’t correctly see on a non calibrated monitor.

Can I visually calibrate my screen?

You could go down this route, but it’s not very accurate or advisable as your eyes are easily tricked and are not a true measurement for colour. The Edward H Adelson image to the right (i) shows 2 squares (A&B) on a chequerboard. In the top image (i), square (A) is darker than square (B). In reality, both squares are identical in colour, as illustrated in image (ii). I couldn’t believe it either, but if you open the image in Photoshop and move the square up, you will see that they are the same. The reason your eyes have been tricked is because of the shadow cast across the chequerboard by the cylinder. If you still want to try and calibrate your screen using your eyes, here’s a useful link http://www.ephotozine.com/article/7-free-online-tools-to-help-calibrate-your-monitor-25803 and good luck.

The kit you will need for accurate prints

To correctly calibrate a monitor you’re going to need a colorimeter. By sticking an ‘electronic eye’ (colorimeter) on your screen and firing a selection (100’s) of colours at it, any colour discrepancies can be detected and your computer programmed to compensate its colour output for the traits of your monitor. The colorimeter we use at Archant is the X-Rite i1 Display PRO and currently retails for about £160. The one I use at home for my image editing (www.stevedocwra.co.uk) is the Datacolor Spyder 4 Pro and retails for about £140. Personally, I prefer the X-Rite i1 Display PRO as there are more options for calibration and the colour temperature is easier to set and control.

Once you’ve got your colorimeter, you’re going to need your screen turned on for at least 30 minutes, which will give the display time to settle. After following the software installation instructions, you will need to reset your monitors settings to the factory default before starting the calibration process, making adjustments to brightness and contrast etc when prompted. The calibration settings we use at Archant are: Gamma response 2.2, White Point 5000°K (D50), Screen Luminance of 120 cd.

White Point

Colour is displayed on a monitor by mixing the pure primary colours : pure Red, pure Green and pure Blue. The white point describes the balance of Red, Green and Blue light when a white colour is displayed on the screen. A white point of 5000k (D50) gives a neutral daylight white. It is recommended to use a 5000K light source for critical viewing of prints. Various print viewing booths with 5000K light sources are available.

Iso Newspaper 26v4 Icc Download

Brightness

There is an ISO standard that specifies a screens brightness of 160 candela/cd for critical inspections of color prints. Ideally you could set your monitor for a brightness of 160 candela/cd and having a viewing booth which matches that brightness level. Running a monitor at this brightness could reduce its life span. A good compromise is 120 candela/cd. Most viewing booths can easily be dimmed to match that brightness level and it is fairly bright for critical color judging.

Gamma response

The gamma value refers to the mathematical gamma function and is used to describe the un-linear response of the monitor. Historically, Mac computers used a gamma value of 1.8 and windows PCs used 2.2. Apple chose 1.8 as it was easier for them to match images on a monitor and a printer when using gamma 1.8. In those days the ICC colour management system was not invented.

With today’s ICC colour Management workflow, you will get equally good results if using gamma 1.8 or 2.2. However, as the most often used workspaces for images (Adobe RGB (1998) and sRGB) use gamma 2.2, it has become the default standard to use gamma 2.2 for the monitor setup.

Tips for calibration and consistent colour correction

1. Locate your computer in the proper environment with moderate ambient lighting and no direct light sources shining on the monitor.

2. Achieve a stabilised room light situation

3. Turn the monitor on at least 30 minutes before calibrating or colour correction

4. Recalibrate your monitor every 2 weeks as there is a screen ageing process.

5. Avoid colourful walls and surfaces around your monitor as this can either reflect onto the screen or influence your colour perception.

6. Don’t colour correct images wearing a bright colourful t-shirt as the colour will reflect onto the screen and result in a colour cast being added.

Now that you’re running a calibrated screen, you should be seeing the same as what we see, but not necessarily the same as what we see to print. The reason for this is that you are viewing the image in an RGB colour space (lots of colours) and we print in the CMYK colour space (not so many colours). Also, we print using the 2 print profiles (ISO Coated v2 300% ECI for glossy magazine and ISO Newspaper 26v4 for newsprint). These profiles are simply look-up tables that describe the properties of a colour space. They define the ink weight, paper stock and colours available in that specific colour space; i.e. the bluest blue or deepest black the printer can produce. If you don’t use a profile, the trio of Red, Green, and Blue values (or CMYK) that make up a colour have no particular meaning — you can say something is blue, but not exactly which shade of blue.

Using the correct profile is the key to a colour-managed workflow. With accurate monitor and printer profiles, your prints will closely match what you see on your monitor. Without profiles, you need to rely on trial and error combined combined with lots of guess work.

How to install ICC profiles on your Windows computer

Right click on the ICC Profile once downloaded and select “Install Profile”.

Any applications (such as Adobe InDesign / Adobe Photoshop etc) that will use the profiles must be restarted to see the new profiles.

How to install ICC profiles on your computer – Apple / Mac

The ICC profile must be placed in the correct folder for your software to use them. (Macintosh HD > Library > Colorsync > Profiles)

Any applications (such as Adobe InDesign / Adobe Photoshop etc) that will use the profiles must be restarted to see the new profiles.

The Grainger Chart below illustrates the sRGB spectrum of colours available through your monitor.

nb. The Grainger gamut is mathematically generated, so expect that not all colours will be viewable.

The Grainger Chart below illustrates the sRGB colour spectrum of colours, softproofed to the destination colour space (CMYK) and the printer profile ISOCoated v2 300% ECI.icc

nb. If the image above was sent to print, it would reproduce something like the image below as a large percentage of the colours are out of gamut.

Colour Gamut

The graphic below shows the comparison of the popular colour spaces that are used for backlit computer displays (sRGB, Adobe RGB & ProPhoto) and the gamut of possible colours that can theoretically be achieved. The solid area inside the various wire frames, shows the popular printing colour spaces and the achievable colours that can be reproduced with CMYK inks on the chosen printer and media. Any colour outside of the solid coloured area is out of gamut and therefore cannot be reproduced by that printing method and would have to be colour corrected by the designer.

nb. Please do not use the generic default USWebcoatedSWOP icc profile that ships with Adobe software as this is intended for the North America markets and not European printing presses. Also the colour space is a fraction smaller than the ISOCoated_v2_300%_ECI profile, so you would have the chance of more out of gamut colours.

Useful links

1. Gamma and White Point Explained by 2. Want to see how well you perceive colour? Munsell Hue Test

Softproof to see how the image will look in print

Now that we are running a calibrated monitor it’s time to bring it all together and see how our image will reproduce when printed. Download the icc print profiles (ISO Coated v2 300% ECI for glossy magazine and ISO Newspaper 26v4 for newsprint) as these are what you will use to softproof the artwork to. Once downloaded, right click on the profile and select “Install Profile” for PC. The icc profile should now be installed on your system and will be available in Adobe Photoshop, Adobe InDesign and Adobe Acrobat Professional.

Open your image in Adobe Photoshop, chances are it will be in the sRGB , AdobeRGB or ProPhoto colour space if you haven’t edited the image before.

To see how the image will look when converted to the CMYK colour space, select VIEW / PROOF SETUP / CUSTOM from the menu in Adobe Photoshop. If the image is to be printed in a glossy magazine, the Device to simulate to would be ISO Coated v2 300% ECI, for newsprint it would be ISO Newspaper 26 v4. Simulate paper colour needs to be ticked as below. OK this and then head to VIEW / PROOF COLOURS. The image should then change slightly as you are now viewing it to the new colour space. To toggle between the 2 views, you can use the keyboard shortcut Ctrl+Y.

The image below shows what the image looks like softproofed to ISO Coated v2 300% (ECI), but what it doesn’t show is if there are any colours that cannot be replicated (out of gamut) in the ISO Coated v2 300% ECI CMYK colour space.

To show colours that are out of gamut of the colour space that you are softproofing to, you need to head back up to the menu and select VIEW / GAMUT WARNING. Depending how you have Photoshop setup, you may have different coloured blobs appear over the image as below.

The green blobs in the image above are showing some shades of red that are outside of the CMYK colour space you’re working in. Unfortunately, if left this way, the red in question would print different to what was viewed on screen as the colour in question cannot be reproduced with CMYK ink. The easiest way to correct for this, is duplicated the image and edit the softproofed image along side the original RGB image and keep comparing the two images side by side. With adjustment levels / curves and masks, you should be able to get the 2 images close in appearance.

A very basic option to correct out of gamut colours

1. Select the Sponge tool in Adobe Photoshop. It’s grouped with the Dodge and Burn tool icons in the toolbar.

2. Select the smallest brush size for the problem area. Set the pressure setting to a low number (in the Tool options bar).

3. Mouse over the problem spots with the Sponge tool, and it will replace the unprintable colour with one close to the colour but printable (in Gamut).

The final step is to save the image out of Adobe Photoshop and in to the correct destination space. EDIT / CONVERT TO PROFILE and in the destination space, select either ISO Coated v2 300% ECI for glossy magazines or for newsprint it would be ISO Newspaper 26 v4 This will save the image out in the correct CMYK format and to the correct ink weight (TAC).

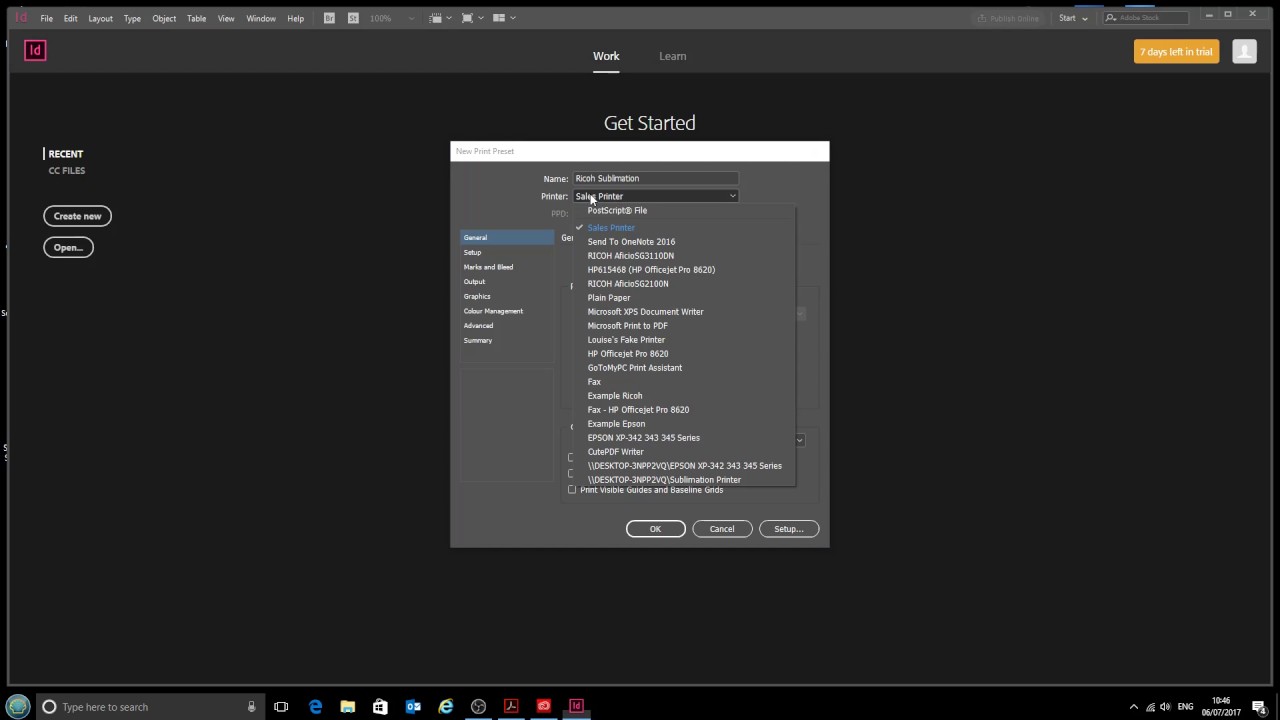

Softproofing using Adobe InDesign

You can softproof your advert in Adobe InDesign (VIEW / OVERPRINT PREVIEW) to turn the overprint preview on. VIEW /PROOF SETUP / CUSTOM) and select either ISOnewspaper 26v4.icc for newspaper print or ISOcoated v2 300% ECI.icc for magazine print and then tick both Simulate Paper Colour and Simulate Black Ink.

The screen grab below is now showing an approximation of how the PDF will print to the specified device.

Softproofing using Adobe Acrobat Pro

To view how your PDF will reproduce in print using Adobe Acrobat Pro you will first need to open the PDF you want to softproof.

Iso Newspaper 26v4.icc -

You will need to have Overprint Preview enabled, from the drop down menu in Adobe Acrobat Professional select (ADVANCED / OVERPRINT PREVIEW). Then you will need to open the Output Preview window from the drop down menu (ADVANCED / OUTPUT PREVIEW) and for the Simulated Profile select the icc that you want to softproof the PDF to, either ISO Newspaper 26v4.icc for newspaper print or ISO Coated v2 300% ECI.icc for magazine print. Also, at the bottom of the Output Preview window is a tick box for Total Area Coverage (TAC), this is the section where you can monitor the ink weight used in the advert. For newspaper print its 240% and for glossy magazine its 300%. Clicking this and changing the values to either 240% or 300% will show you if the advert is over saturated in ink by covering the area with a coloured patch. If any of your advert is over ink weight, the section in question will reproduce darker than expected.